Direct-to-film (DTF) transfer technology is revolutionizing printing by offering high-quality, accurate prints on film and various materials within 24 hours. This innovative process involves meticulous preparation, layer-by-layer ink application, and strict quality inspection. DTF's unprecedented speed, efficiency, and color accuracy make it ideal for businesses seeking prompt order fulfillment, particularly in custom T-shirt designs, promotional materials, and short-run packaging. Advanced machinery, precise calibration, and standardized procedures ensure consistent top-tier results, while automation streamlines workflows to meet diverse customer demands promptly without sacrificing quality.

In today’s fast-paced market, speed is paramount for businesses. Direct-to-film (DTF) transfer orders offer an innovative solution, fulfilling requests within a remarkable 24 hours. This article delves into the world of DTF printing, exploring its benefits and revolutionary impact on turnaround times. From understanding the process to ensuring quality and streamlining workflows, we uncover how DTF technology is transforming order fulfillment. Discover case studies showcasing successful implementations and the key advantages that make DTF Transfer a game-changer for businesses seeking rapid, high-quality results.

- Understanding Direct-to-Film (DTF) Transfer: The Process Unveiled

- Benefits of DTF Printing for Rapid Order Fulfillment

- How DTF Technology Revolutionizes Turnaround Times

- Ensuring Quality and Consistency in 24-Hour DTF Prints

- Streamlining the Workflow: From Design to Delivery

- Case Studies: Successful Implementation of 24-Hour DTF Transfer Orders

Understanding Direct-to-Film (DTF) Transfer: The Process Unveiled

Direct-to-film (DTF) transfer is a cutting-edge printing technology that has revolutionized the way we produce custom prints and orders, especially in the context of film and photography. This innovative process allows for the creation of high-quality, accurate prints directly onto film, eliminating the need for traditional intermediate steps. With DTF, orders can be fulfilled with remarkable speed and efficiency, ensuring clients receive their desired films within a remarkably short 24-hour turnaround time.

The DTF transfer process involves several precise stages. It starts with preparing the film, ensuring its surface is clean and free from any contaminants. Then, a specialized print head applies ink or dye onto the film, creating a vivid and detailed image layer by layer. This method enables the reproduction of complex designs, photographs, and graphics with exceptional precision and color accuracy. Once the printing is complete, the film undergoes careful inspection to meet quality standards before packaging for delivery, ensuring a seamless experience for customers who value prompt and reliable DTF prints.

Benefits of DTF Printing for Rapid Order Fulfillment

Direct-to-film (DTF) transfer printing offers a game-changing solution for businesses aiming to provide rapid order fulfillment. This innovative technology enables efficient and precise printing directly onto various materials, such as fabrics, plastics, and metals. By utilizing DTF Printing, companies can significantly reduce production time compared to traditional methods, allowing them to meet tight deadlines and accommodate rush orders without compromising quality.

One of the key advantages is its speed and versatility. With DTF Transfer, orders can be processed and printed within a matter of hours, ensuring quick turnaround times. This is particularly beneficial for custom product requests or limited-edition items where time-sensitive delivery is essential. Moreover, DTF Prints provide vibrant, durable results, making it suitable for various applications, from promotional merchandise to short-run packaging.

How DTF Technology Revolutionizes Turnaround Times

Direct-to-film (DTF) technology is transforming the way orders are fulfilled, particularly in print and production industries. This innovative process eliminates traditional steps, revolutionizing turnaround times for custom prints and designs. With DTF Transfer, the direct application of ink to a film allows for faster and more efficient production compared to conventional methods.

By streamlining the printing process, DTF Technology ensures that customers receive their orders within a remarkable 24-hour timeframe. This rapid response is a game-changer, especially for businesses requiring quick turnaround solutions. Whether it’s custom T-shirt designs, promotional materials, or specialized prints, DTF Printing offers a dynamic and responsive approach to meeting client demands promptly, providing businesses with a competitive edge in today’s fast-paced market.

Ensuring Quality and Consistency in 24-Hour DTF Prints

In the fast-paced world of direct-to-film (DTF) transfers, where speed is paramount, maintaining quality and consistency can seem like a daunting task. However, with meticulous attention to detail and cutting-edge technology, it’s achievable to deliver top-tier DTF prints in just 24 hours. The process involves rigorous quality checks at each stage, from raw material selection to final print inspection. Standardized procedures ensure that every DTF transfer follows the same high standards, guaranteeing consistent results time after time.

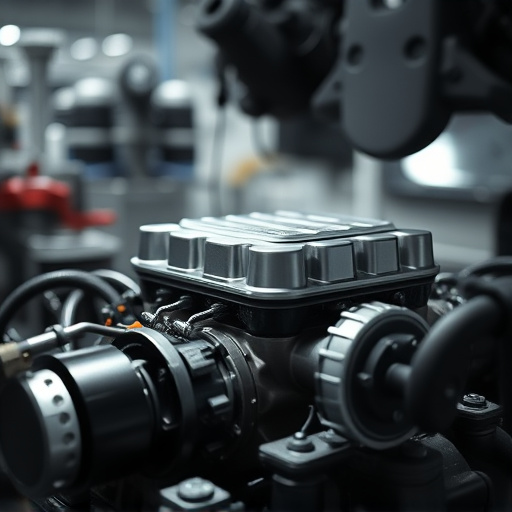

Moreover, advanced printing machinery plays a crucial role in upholding quality. Modern printers equipped with precise calibration and color-matching capabilities produce vibrant, detailed prints that rival traditional methods. Regular maintenance and calibration of these machines further contribute to maintaining consistency across all orders fulfilled within the 24-hour window. This commitment to excellence ensures that customers receive not just swift service but also reliable, high-quality DTF prints for their projects.

Streamlining the Workflow: From Design to Delivery

In today’s fast-paced world, time is a valuable commodity, especially in the printing industry. Streamlining the workflow from design to delivery is no longer an option but a necessity for businesses offering DTF (Direct-to-film) transfer services. This innovative process revolutionizes traditional printing methods by enabling quick turnaround times, often fulfilling orders within 24 hours.

By implementing efficient systems and technology, DTF printing experts can automate various stages of production. From initial design input to final print output, the workflow becomes a seamless symphony of operations. Automated cutting, precise imaging, and rapid drying technologies ensure that each step is optimized, minimizing delays and maximizing productivity. This streamlined approach allows for a steady stream of high-quality DTF prints, catering to diverse customer demands in a timely manner.

Case Studies: Successful Implementation of 24-Hour DTF Transfer Orders

In today’s fast-paced world, where time is a premium, direct-to-film (DTF) transfer orders with 24-hour turnaround times have become a game-changer in the printing industry. Case studies from leading DTF printers highlight successful implementations of this rapid service. These companies have optimized their processes to ensure that orders, once received, are swiftly executed and delivered without compromising quality.

The key to their success lies in streamlined workflows, advanced technology, and well-trained staff. By investing in state-of-the-art DTF printing equipment and software, these businesses can automate various stages of production, reducing human error and increasing efficiency. As a result, customers benefit from fast turnaround times without sacrificing the quality and precision of their DTF prints.